The GeometⓇ treatment is a non-electrolytic, anticorrosive treatment that uses a patented aqueous solution.

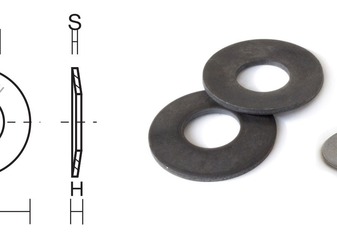

This thin protective coating layer (between 5 and 10 µm) contains zinc and aluminum in lamellar form and is applied to components by dipping or spraying.

Before proceeding with the coating of the parts, they are subjected to sandblasting to clean them of any impurities, making the surface rough. After this step, the aqueous solution of zinc and aluminum will be applied by dipping or spraying.

Once treated, the parts will take on the characteristic matte silver color.

The GeometⓇ treatment is an alternative to the Dacromet 500Ⓡ treatment because the solution to be applied does not contain heavy metals like chromium, which is present in the latter.

There are 2 types of GeometⓇ treatments: Geomet 321Ⓡ and Geomet 500Ⓡ, with 2 different grades of finish A or B, which confer greater or lesser lubricating properties to the part.

Among the main advantages, this special anticorrosive coating, unlike hot-dip galvanizing, does not cause hydrogen embrittlement, a fundamentally important advantage for the treatment of fasteners with resistance class from 8.8 to 12.9.

It is extremely ductile with great capacity to adapt to elastic deformations, with heat resistance up to 280°C.

The only disadvantage, as with galvanizing, is that the GeometⓇ treatment cannot be applied to components with cavities, such as screws with recessed hexagons, due to the risk of accumulation in the hollow part, compromising the use of the part.

Therefore, its application on screws and bolts with a diameter less than M5 is not recommended.

Subscribe to our newsletter to receive updates on our products.

Added to quote

Added to quote