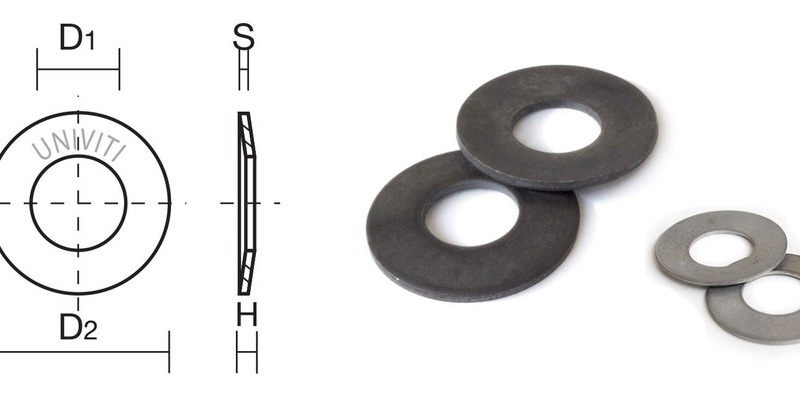

Disc spring is a mechanical component within the washer family, are easily recognized by their distinctive conical shape, which gives the part elasticity and the capacity to absorb high loads even in a small housing space.

This item is typically used in bolted joints subjected to dynamic loads because it has high resistance and the ability to dampen vibrations, providing a cushioning effect, in addition to a low tendency to deform.

These characteristics make them the ideal item for various industry sectors.

Belleville washers can be classified into three groups, as specified by DIN 2093, based on the thickness of the part.

The first group includes all items with a thickness of less than 1.25 mm, the second all washers with a thickness ranging from 1.25 mm to 6 mm, and the third and final group includes parts with a thickness from 4 to 16 mm.

Added to quote

Added to quote