Cotter pins are mechanical fastening elements that prevent a nut or pin from sliding out of its seat.

There are several types of cotter pins, among the most commercially available we can find: standard, elastic, snap, and ring types.

In the standard form, the cotter pin looks like a nail cut in half longitudinally. It is actually a metal bar with a semicircular section, folded back on itself after forming an eye with two ends of different lengths to facilitate opening.

In our product range, you can find:

Steel Cotter Pin. DIN 94. ISO 1234 and UNI 1336

For this type of cotter pins, once inserted into the hole of the pin, it is possible to resize or bend the ends as needed.

Elastic cotter pins, also known as "elastic safety pins" or "R-Clips," are recognized by the characteristic "R"-shaped formed part, designed specifically to flex without deformation, thus allowing reuse. In this case, the straight part is inserted into the hole, while the other shaped part will directly grip the pin. This particular article is used especially in situations where disassembly and reassembly are frequent, such as in agricultural machinery, those for moving soil, or for mowing.

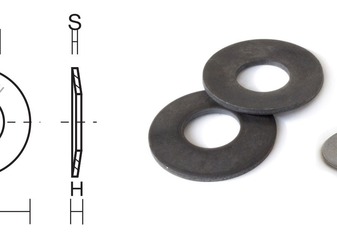

The third type of cotter pin, the snap type, is also called a "snap pin". This item consists of an external snap ring and a rod made of material more resistant than that of the elastic cotter pin.

This item is indeed used for fixings with significant loads, where it is necessary for the item in question to have great resistance. The ring ensures that the central nail does not exit the pin in which it has been housed.

Among our items, you can find:

Snap Pin in steel. DIN 11023

Lastly, the ring cotter pins are made from a metal wire coiled into a ring on multiple turns, with one of the ends bent inward. This item is mainly used for securing parts on sailing boats, as the round shape without protruding parts does not pose a danger.

Write to commerciale@univiti.it to request a quote!

Added to quote

Added to quote