Types of Steel: What They Are and Characteristics

According to the American Iron & Steel Institute (AISI), the association of North American steel producers, there are 4 main categories for the classification of steel:

- Carbon steel;

- Alloy steel;

- Tool steel;

- Stainless steel.

Carbon steels represent 90% of the total production of this metal. This steel is widely used for its characteristics related to ease of processing but, at the same time, it is a material highly susceptible to corrosion and sensitive to high and low temperatures. Generally, carbon steels do not contain other elements within the alloy and, based on the percentage of carbon present in the material, can be divided into 3 categories:

- Mild (up to 0.3%);

- Medium (0.3-0.6%);

- High carbon content (over 0.6%).

These steels are highly resistant and, for this reason, are used for different realizations: knives, high-tension wires, automobile parts, etc.

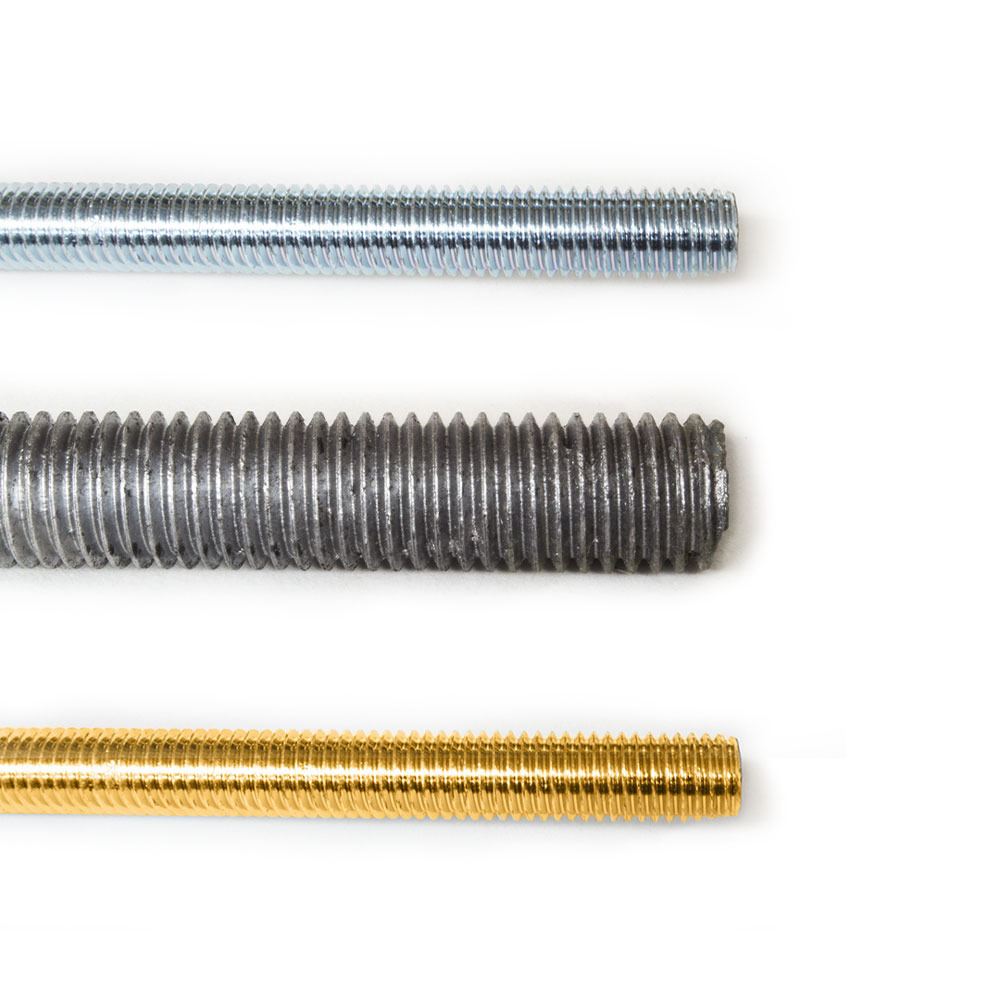

Unlike carbon steels, alloy steels contain bonding elements like manganese, silicon, nickel, chromium, copper, and aluminum. These substances are added in specific percentages depending on the chemical characteristics desired for the final product. These steels are mainly used in mechanics and in the realization of conduits.

Like alloy steels, tool steels also contain other elements within them. Specifically, it is possible to find the presence of tungsten, molybdenum, cobalt, and vanadium. The quantities are variable and depend on the need to increase the heat resistance and durability of the final product. In this way, such steels are ideal for operations that involve drilling and cutting.

Stainless steel is, arguably, among the most famous.

Also known as inox, it is a material highly resistant to oxidation, therefore, steel that does not rust, thanks to the presence of chromium in the alloy (between 10% and 20%). Most of the fastening products on the market are made of stainless steel A2 and A4. The two materials have very different characteristics: A2 is widely used in various sectors, including the chemical industry; A4 is used in different fields, such as shipbuilding.

More than 100 types of stainless steel can be classified in the stainless steel class, making it a highly versatile and customizable alloy. Not all stainless steel is the same, and it is important to know the possible differences.

Stainless Steel

It is a common mistake to talk about stainless steel to describe steel in general.

This association is incorrect because there is a clear distinction between stainless steel and traditional steel, noticeable in the composition of the alloys. As already mentioned in the previous paragraph, stainless steel is characterized by a significant presence of chromium (about 12%) associated with 50% iron.

There are different types of stainless steel, but a particular mention deserves the 304 and 316 steel class. These are two types of steels widely sought after for their corrosion resistance. However, it is good to remember that even inox is not exempt from corrosive phenomena: precisely to prevent and slow down these phenomena, such material can be subjected to specific treatments, such as passivation.

Mild and Unalloyed Steels

Mild steel is one of the most widespread forms of steel, widely used in the steel industry. The name derives from its chemical composition. Indeed, mild steel can be described as the mildest of carbon steels because it contains a relatively low amount of carbon. The percentage of carbon present in these alloys varies and, consequently, determines the variation in the mechanical characteristics of steel, such as mechanical strength, hardness, hardenability, and wear resistance, but will decrease malleability, ductility, toughness, and weldability.

Based on the percentage of carbon, we have:

- Extra mild steels (C<0.008%)

- Mild steels (C between 0.008% and 0.1%)

- Semi-mild steels (C between 0.1% and 0.4%)

- Semi-hard steels (C between 0.4% and 0.55%)

- Hard steels (C between 0.55% and 0.8%)

- Extra hard steels (C between 0.8% and 2.06%).

Mild steel is not part of the family of alloy steels since, as specified, it does not contain large quantities of elements other than iron.

This is indeed the main reason why alloy steels are distinguished from unalloyed steels.

The distinction, therefore, concerns the presence or absence of other alloying elements.

Alloy steels are alloys composed not only of Iron and Carbon but also of other elements that allow improvements to the chemical-physical structure: Chromium, Aluminum, Boron, Titanium, silicon, manganese, nickel.

Alloy steels have numerous advantages:

- Hardenability

- Strength

- Toughness

- Corrosion resistance

- Hot hardness

These additional elements are incorporated into the alloy during the manufacturing of the metallic material to improve its mechanical and/or technological properties. The presence of one element rather than another and the quantity in which this is present, influence the final characteristics of the alloy.

Thus, if alloy steels have additional elements in their composition, on the contrary, unalloyed steels are made of alloys in which other elements are present in a quantity lower than that conventionally established by the UNI EN 10020 standards. These are steels in which the presence of such elements is minimal.

High and Low Strength Steels

At this point, it will be clear that the different chemical compositions of the elements give rise to steels with different characteristics.

Among these characteristics, resistance, or the ability to withstand an impressed force without undergoing deformations, is particularly relevant.

Based on this attribute, it is possible to distinguish between:

- High-strength steel, better known as high resistance, characterized by a mechanical resistance superior to traditional steel by about 60-125%;

- Low-strength steel, i.e., steel with a low carbon content and a limited amount of other alloy elements. In these cases, after processing for plastic deformation, these materials reach breaking loads between 350 and 600 N/mm2.

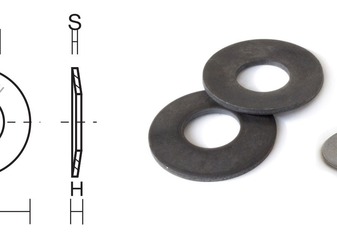

The choice of the type of steel is determined based on the resistance and plasticity characteristics required for the finished product. For example, when fastening elements are used in particular structures such as pressure vessels, low-resistance steels are usually prescribed, both to avoid explosions due to sudden breaks of the screws and also because these steels allow a certain elongation before breaking.

The regulation that governs the mechanical and physical characteristics of fasteners is UNI EN ISO 898-1, a standard that defines the resistance class criteria for screws and bolts.

Steel Production

Over time, the production of steels has seen various changes until reaching the most modern technologies used today.

Tracing back the history of steel production, the first steel furnace probably dates back to the 14th century, a period during which a pit was dug near a rock wall. In this pit, coal combustion was carried out, and it was sheltered by a stone slab. Subsequently, systems were studied to obtain metals of superior quality. In fact, the size of the furnaces grew, and more powerful draft systems were put into practice.

Today, most production takes place in large steel plants. Depending on the technology used and the type of steel to be obtained, two possible production cycles are used:

- Steel produced with a blast furnace;

- Steel produced with an electric furnace.

When steel is produced with a blast furnace, various raw materials such as ferrous ore, coke, and flux are worked. These are mixed and melted to separately obtain cast iron and other secondary elements. At this point, elements such as scrap iron or others will be added to obtain steel with the desired characteristics. Subsequently, the steel is cut into large blocks, also known as ingots or slabs.

These blocks will be worked to give them the necessary shape and, therefore, produce sheets, bars, tubes, etc.

In the second case, where the production cycle takes place with an electric furnace, the processing steps are fewer. Indeed, scrap iron is melted together with other elements to obtain semi-finished products. These will then be subjected to hot or cold galvanizing treatments.

How to Read Steel Codes?

We have learned that to choose the right product based on one's needs, it is important to know it. In this regard, knowing how to read steel codes is an additional piece, useful for the final choice.

In general, the designation of steels follows the guidelines indicated by the UNI EN 10027-2006 standard. According to this indication, there are two types of codes for steels:

The numeric code is easily recognizable, but one must know it to understand its meaning. It is indeed a code of the type 1.XXYY where:

"1" indicates the type of steel; "XX" describes the steel group; "YY" represents the sequential group of the steel alloy.

The second type of code, the alphanumeric one, is distinguished into two main groups:

Steels that belong to Group 1 are designated based on their use and their mechanical characteristics. This category includes well 8 subgroups within which are usually found steels used in the raw rolling state. Each subgroup is described by a letter of the alphabet (for example, the letter "S" is used to indicate structural steels)

In general, therefore, steels that belong to this group are described with a code composed of:

- the letter of the subgroup;

- number equal to the minimum prescribed yield strength.

There are cases, such as structural steels, where the code is normally accompanied by additional information such as the degree of resilience and the state of supply/quality of the steel.

For example, the code S 235 JR G2 can be explained as follows:

- S=structural steel;

- 235= yield strength expressed in N/mm2;

- JR= resilience > 270 at 20 C;

- G2= calm steels.

Steels that belong to Group 2 are designated based on their chemical composition. These can be divided into 4 types:

- unalloyed;

- weakly alloyed;

- alloyed;

- rapid.

In this group, the code is composed of:

- letter;

- carbon content;

- other specific values for type.

For example, for the class of unalloyed steels, the code is composed of the letter C associated with the carbon content multiplied by 100, therefore C45.

Added to quote

Added to quote