Added to quote

Added to quoteSearch the more than 56,000 items in the catalog.

When mounting tools, objects, or furniture, the question we often ask ourselves is "how much more can I tighten?". Properly tightening nuts and bolts means preventing them from loosening or getting damaged.

This depends on the torque settings of bolts, nuts, or screws, or rather, the force with which we tighten them. The more force used, the more the threads crush and grip onto each other.

Knowing the measurement of a torque setting for screws, bolts, or nuts is important to prevent them from getting damaged. When we tighten a bolt with a wrench, the force that is generated is known as the arm and is equal to the length of the wrench itself.

According to the international measurement system, torque is measured in Newton – Meters (N.m), a value that, when converted into Kg, is equivalent to 9.81 kilograms of force.

Therefore, assuming a force of 10Kg on a one-meter-long bar, the value of the torque applied at the center of the bolt will be 98.1 N.m.

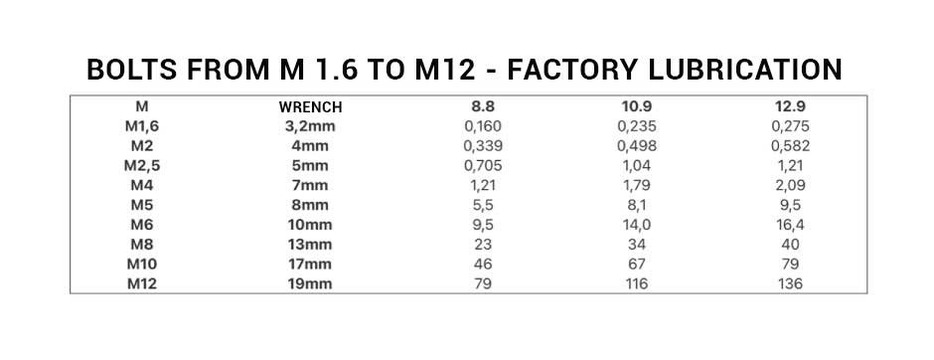

Making calculations every time you face an assembly can be complicated. For this reason, before getting to work, it is useful to have a torque table at hand, a chart that indicates the correct values based on the most used material in mechanical fields, screws with material class 8.8 and 10.9 as well as stainless steel screws.

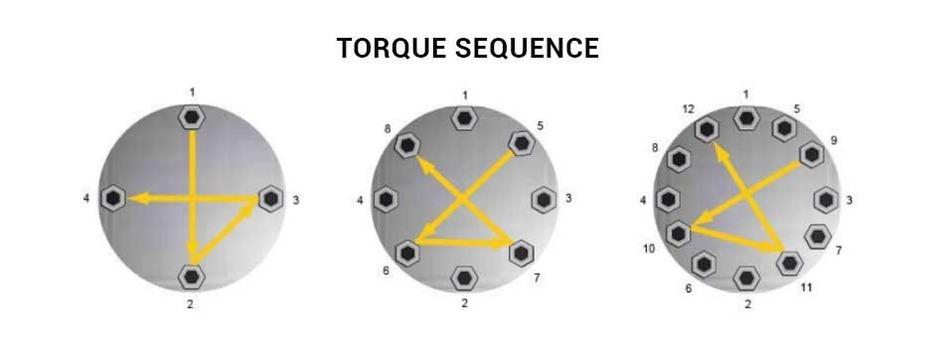

The tool that allows for more precise and controlled work is the torque wrench for torque settings, available on the market in different types (the most common is the click type) and allows a control mechanism capable of signaling the achievement of the set torque value. Using this tool is essential to avoid damaging screws and bolts because it alerts us with a "click" when it's time to stop. When the torque wrench is set, proceed through a tightening sequence:

So, how much should bolts be tightened? At this point, it's clear that, during assembly or screwing, adhering to the torque settings is important to prevent bolts and nuts from deforming, breaking, or loosening in no time.

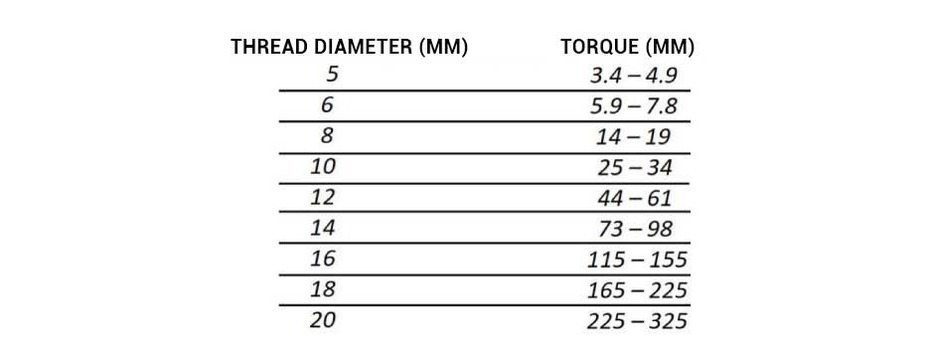

Below, we report indicative values to consider in relation to the diameter of the thread and torque:

While bolts are designed to be used in already threaded holes and then tightened with nuts, screws can be used in already threaded holes but are also capable of piercing a material and, therefore, creating an internal thread.

When a screw meets a threaded hole, a so-called screw preload is generated, which is a stretching of its shank that is stressed up to a max of 90% of the yield limit (when the material changes its internal structure).

Another mechanism that is important to know is that of threaded couplings: it's the friction generated under the head of the screw and in the threading when the former is tightened. Choosing the right class of a screw is therefore important to sustain the tension.

The resistance is usually indicated on the head of the screw where it is easy to identify 1 or 2 figures.

To calculate the tensile strength, the first value can be multiplied by 100 (example 8.8 = 8x100= 800 N/m. Conversely, to calculate the yield limit, the two figures should be multiplied together and by 10 (example 8.8= 8x8x10= 640 N/m).

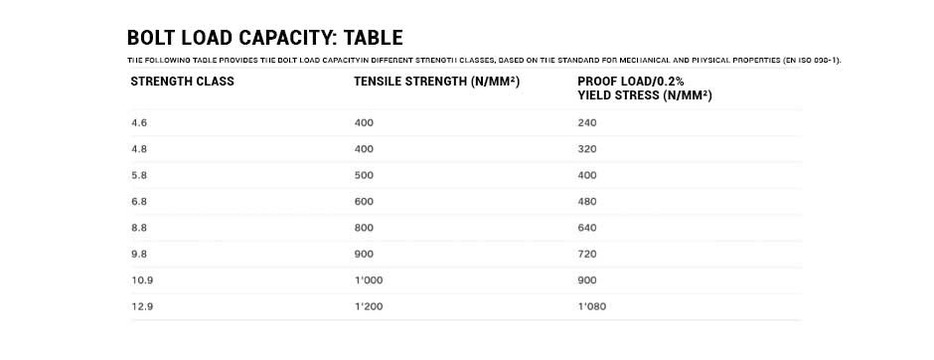

Should the calculations prove complicated, below is the table with reference values:

For more information or advice on the most appropriate choice, send a request to our commercial team, writing to the email:commerciale@univiti.it