Added to quote

Added to quoteSearch the more than 56,000 items in the catalog.

As can be inferred from the name, this thread gets its title from its particular shape. Indeed, the profile of a thread made in this way presents the shape of a symmetric isosceles trapezoid and falls into the class of non-triangular threads. The dimensions of the trapezoidal threads are expressed in millimeters, and the angle formed by the sides of the thread determines a profile angle of 30°.

The main characteristic of this type of thread is found in its capacity to transmit motion and withstand a very high friction coefficient.

This makes a screw with such thread self-locking. This type of threading finds its main field of application in the transmission of relative motion between mechanical organs.

What does this mean? In practice, trapezoidal profile screws are used to transform their rotary or circular motion into linear motion.

Therefore, considering the screw - nut system, through a rotary motion impressed on the screw, a linear translational motion can be obtained on the nut. Trapezoidal screws can thus also be defined as maneuvering screws, since by rotating the screw or the nut, a reciprocal displacement of two mechanical organs can be obtained.

Therefore, to exploit the full potential of such threading, the rotary movements must be converted into translational movements.

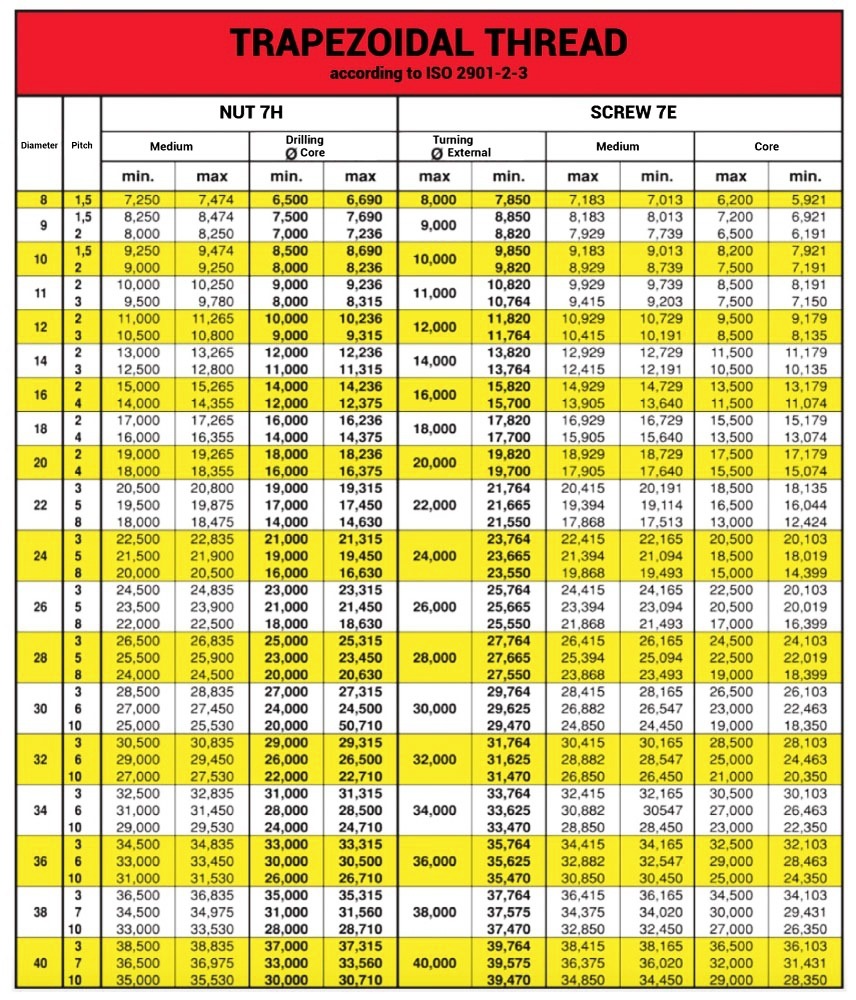

Among the range of trapezoidal profile threads, the most widespread and known is the ISO 2901 thread, which ensures the transmission of significant forces and a very high tolerance of movement. In general, the entire range of ISO trapezoidal threads is used for the transmission of significant forces with high levels of precision.

When talking about screws and nuts with trapezoidal threads, we are referring to mechanical items that are used for fastening and for movement.

The fields of application are varied, ranging from DIY to the industrial world. Specifically, the trapezoidal thread finds wide application in production equipment. Below are some examples of industrial applications of screws with trapezoidal threading:

By this point, it will appear clear that the main advantage of using this thread lies in its ability to transmit motion and be, at the same time, self-locking.

Indeed, the threaded part of the screw does not need to be fixed in the desired position, and the transformation of movements, from rotary to translational, occurs with the help of a nut that pushes the component of the nut onto the screw.

Given the high potential of trapezoidal threading, the main advantages deriving from its use are:

For completeness of information, below is the table related to the dimensions for ISO 2901 metric trapezoidal threads:

For more useful and interesting information about this product, subscribe to our newsletter. If you want to receive a free quote, contact our commercial team by writing to commerciale@univiti.it