In this new article, we return to the topic of galvanizing, focusing on the theme of galvanizing thickness.

As reported in a previous article that explains this procedure well, the term "galvanizing" refers to the protective zinc coating applied to steel parts. This procedure, necessary to protect parts from corrosion, can be carried out in different ways:

- hot-dip

- thermal spraying

- electrolysis.

Although new methodologies and protective treatments are making their way into the sector, the most used treatment is that of hot-dip galvanizing, a procedure that finds wide use in the infrastructure and construction sector as it offers greater protection from atmospheric agents, also ensuring an excellent quality-price ratio.

A characteristic related to the durability of the galvanizing is certainly the thickness. This varies according to the following criteria:

- type of galvanizing

- component to be galvanized

- method of galvanization.

In general, the thickness of hot-dip galvanizing is the process that guarantees better results. But let's discover together how thicknesses are defined and what there is to know about this topic.

UNI EN ISO 1461: the regulation that governs the thickness of galvanizing

As required for most components produced and sold according to law, there is also a specific regulation to adhere to for hot-dip galvanizing. In fact, UNI EN ISO 1461 is an international regulation that regulates and defines what the minimum thicknesses to be applied are to consider the protective layer of zinc compliant.

Just like for other products, also for galvanized ones, there are parameters and tolerances within which to act to respect the discipline. Specifically, according to ISO 1461, the average thickness must be:

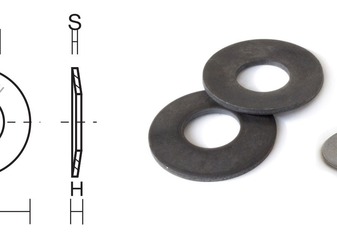

- At least 45 microns (1 thousandth of a millimeter) for steel thickness < 1.5 mm;

- At least 55 microns for steel thickness between 1.5mm and 3.0mm;

- At least 70 microns for steel thickness between 3.1mm and 6.0mm;

- At least 85 microns for steel thickness > 6mm.

The values just reported apply to galvanizing performed on "batch" components, on products already formed or already assembled. In treatments applied to these products, the thickness is much greater than that applied to, for example, pre-galvanized sheets where the zinc layer can reach 20-30 microns.

In general, the process requires that the component to be galvanized is first checked to ensure that the surface does not have defects or irregularities. Once the component has been treated, it is rechecked and deemed suitable.

This verification system occurs for every type of component regardless of whether it is part of hot-dip galvanized bolting, structural bolting, or whether it is hot-dip galvanized tie rods and anchor bolts.

As required by the UNI EN ISO 1461 standard, Univiti provides its specialized partners with products that adhere to the specifications present in the regulation. Here is the complete list of hot-dip galvanized article range.

How is the thickness of galvanizing measured?

Once the product has been galvanized, a final inspection phase is necessary to verify that the final product is in line with the UNI EN ISO 1461 standard. But how to proceed and how to measure the galvanized thickness?

There are 4 ways to measure the thicknesses of galvanizing:

- Use of thickness gauges based on the magnetic principle.

This is a simple, fast, and inexpensive method that exploits the operation of some work instruments, defined precisely as coating thickness gauges, designed specifically for this purpose;

- Stripping and weighing.

- Weighing the element before and after galvanizing;

- Optical microscopic observation.

Measuring the zinc layer thickness correctly means determining and ensuring the product's quality before it is shipped to the customer/client and thus marketed.

Added to quote

Added to quote