What Are Lifting Accessories?

As reported in the Italian reference standards, "lifting accessories are components or equipment not connected to lifting machines, which allow the lifting of the load, placed between the machine and the load or on the load itself, or intended to become an integral part of the load and to be placed on the market separately; slings and their components are also considered lifting accessories."

These are therefore equipment or elements that facilitate lifting work but must necessarily meet legislative provisions and requirements to be considered suitable for worker health and safety. In fact, these accessories must be used according to the loads to be handled and following the manufacturer's instructions, who, in turn, will have complied with the reference standards for the production of such components or equipment. The accessories must display the following indications:

- Material identification;

- CE marking or equivalent plate welded on the accessory and bearing legible indications related to the element (e.g., manufacturer's name, standard, sling symbol, capacity, etc.);

- Documents or instruction booklet indicating intended use, limits, instructions for assembly, use, maintenance, and the static test coefficient used.

Considering these requirements, it is possible to choose and rely on safe suppliers capable of providing numerous products and equipment in line with the directives. Among the components used in the lifting accessories sector, we can remember:

Eyebolts, Shackles, Karabiners: How to Choose the Right Product

To provide more comprehensive information on choosing the right product, below we delve into various types of lifting accessories and their use.

Lifting Shackles

Also known as lifting lugs, shackles are the most common lifting component. Used to connect steel ropes, synthetic cables, and chains to the load or other components in industrial, marine, and nautical applications, these elements allow for the effective and safe movement, suspension, fixing, or towing of loads of any shape and size.

The type and size of shackles to be used should be decided by competent personnel, evaluating:

- The weight of the load to be lifted.

- The position of the load's center of gravity.

- The possible angle between the pull and the vertical.

- The shape and dimensions of the components to be connected (hooks, eyebolts, tensioners, etc.).

- Other possible factors (high or low temperatures, corrosive atmosphere, etc.).

Lifting Eyebolts

Eyebolts are forged metal rings to be fixed to loads to allow their lifting or anchoring. For load handling, eyebolts act as lifting points, i.e., an interface with slings and lifting straps, while for load securing, they are used as anchoring points to insert the hooks of the securing chains on transport vehicles.

Eyebolts and lifting and securing attachments are divided into:

- Threaded types (male or female)

- To be welded

- To be bolted

The lifting and securing attachment can serve both for lifting and as an attachment point to secure the load with ropes, chains, or synthetic band fastenings on truck beds, trailers, or railway wagons. The low-strength steel fixed eyebolts have largely been replaced by modern fixed or swivel types in high and very high-strength steel, far superior in capacity, versatility, and safety.

Including both DIN or ISO standard fixed eyebolts and more modern and high-performance models, lifting eyebolts allow the effective and safe movement of loads of any shape and size.

Fireman's Karabiner

The fireman's karabiner in zinc-plated steel with quick spring closure (snap closure) proves to be a valid element in combination with chains and steel ropes.

The quick closure of the karabiner is certainly the greatest advantage in using such an element, which finds application in various fields, from agriculture to construction to mechanics. The karabiner is intended to quickly attach and detach ropes or chains to each other or to rings and eyes and is mainly used to join two elements quickly and safely. It is reusable.

Functions: towing, securing loads in the industrial and naval fields, small moorings, fences, chain joining, general non-heavy uses; its use for lifting is not permitted.

Tensioners for Ropes and Chains

Tensioners are mainly used to tension steel ropes (more rarely chains) in fixed applications such as stays, bracing, tensioning of overhead lines, tensile structures, suspension bridges, fences, fastenings, naval riggings, etc.; they are also used in spacers and multiple lifting complexes (employing multiple arms or straps simultaneously) to lift loads horizontally.

Wire Rope

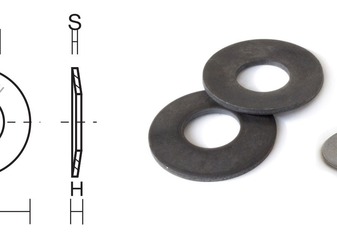

Thimbles Thimbles, inserted in the loops of steel or fiber ropes, extend their lifespan, ensuring an adequate bending radius and protecting the rope from abrasion against the accessories connected to them.

Cable Clamps for Steel Ropes (cable clamps)

Clamps for steel ropes also allow non-specialized personnel to form a loop without any specific equipment, but only a hex key (preferably, a torque wrench). They are used in fixed applications such as load anchoring, naval riggings, suspensions, bracing, fences, towing, naval loading ramps, and much more.

Regulations Related to Lifting Accessories

To ensure that lifting equipment and tools comply with the required standards, you can request the following certificates and documents from your trusted supplier.

Regarding laboratory analyses, you can request:

- Chemical analysis;

- Metallographic analysis;

- Tensile test;

- Fatigue test.

As for the certificates, the requester can have at their disposal:

Not all these documents can be requested for all products. For this reason, it is advisable to always turn to professional suppliers, capable of providing useful information about the documentation and the right product to choose.

Periodic Maintenance of Lifting Accessories

Inspections and checks on lifting accessories are essential, as well as mandatory, to prevent any deterioration from causing dangerous situations. In general, we can list the following types of maintenance:

- Daily visual inspection (does not require records);

- Frequent inspection (every three months or sooner and must be recorded);

- Periodic inspection (more thorough, performed once a year and must be recorded);

- Inspection in case of an accident.

These checks are generally carried out by the managers overseeing the works and who verify compliance with the regulations. Furthermore, the supplier to whom you turn plays a fundamental role: he too will carry out checks on the products and guarantee their compliance for a safe purchase.

For more information on lifting accessories, subscribe to our newsletter.

Contact us at commerciale@univiti.it to receive a free quote.

Added to quote

Added to quote