Sealing rings are mechanical elements designed to accommodate nuts and bolt heads. With a circular and flat structure, DIN 7603 sealing rings are mainly used as spacers in mechanical assemblies and distribute the load evenly over a large surface. In this article, we will define the characteristics of such elements and the various fields in which they are used.

DIN 7603 Sealing Rings

Widely used in the automotive sector, in the construction of turbochargers, electrical systems, and earth-moving machines, DIN 7603 sealing rings are components capable of reducing the risk of surface damage caused by other threaded elements.

This particular type of washer finds application in all the sectors mentioned above because it guarantees good resistance to high temperatures and corrosion.

Below, we summarize the main reasons for choosing to use a DIN 7603 sealing ring:

- Regulate distance on fastening elements;

- Provide a durable and reliable seal;

- Maintain the seal under pressure;

- Protect from external damage;

- Achieve simultaneous sealing and locking;

- Seal fluids such as oil and fuel;

- High-pressure resistance;

- Prevent nuts and bolts from rotating and slipping;

- Even distribution of nut pressure on the surface.

How Many Types of DIN 7603 Sealing Rings Are There?

DIN 7603 sealing rings are mainly available in the following versions:

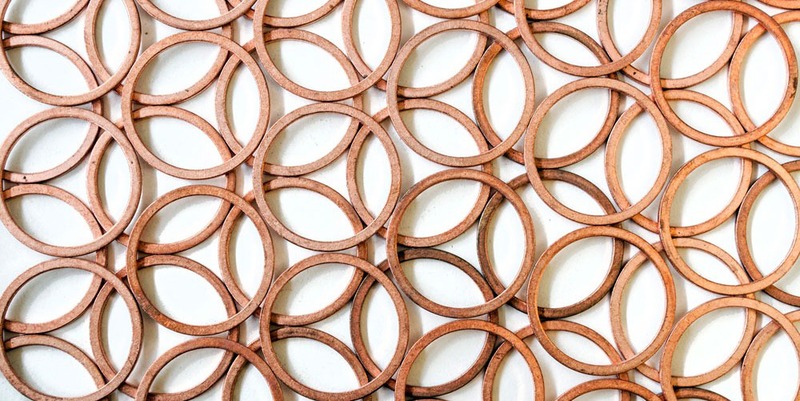

- Copper rings, which have very high corrosion resistance. These products undergo a special preheating treatment that softens the metal, making it easier to insert into irregular areas of assemblies. Due to this characteristic, they are used in various sectors, except in areas where there is exposure to strong acids.

- Aluminum rings, like copper products, this second type is applicable in various sectors and is corrosion-resistant. Aluminum indeed offers good corrosion resistance.

The choice of the right ring will therefore depend on the final destination and the type of assembly. In any case, it is advisable to rely on experienced suppliers capable of indicating the most suitable element for different needs.

What Is an O-Ring?

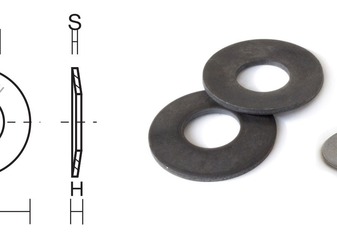

O-rings, commonly named for their circular shape, appear as "crushed washers" due to their minimal thickness.

These products are lightweight, corrosion-resistant, and more durable than a rubber element. Given their versatility of use and the benefits derived from their application, these rings are used in various sectors and workplaces.

From repair workshops, to the maintenance of industrial machinery, to companies dedicated to unique transport, the rings provide resistance and solidity even in the most difficult applications. Moreover, thanks to their high conductive capacity, these elements are used in particular sectors like hydraulics, fuel and oil pipelines, in screw connections in the engine block and cylinder heads, in diesel engines, injector units, hydraulic systems, and motor pumps.

Thus, it is a spacer that, in every application, manages to maximize performance and ensure a solid seal of the assembly over time.

How Do You Measure an O-Ring?

To choose the best product, it is important to select one of the right size and measure.

The measurements of an o-ring result from the value of the cross-section and the inside diameter. A caliper is certainly a useful tool in this regard, capable of providing the correct dimensions of the element.

Added to quote

Added to quote